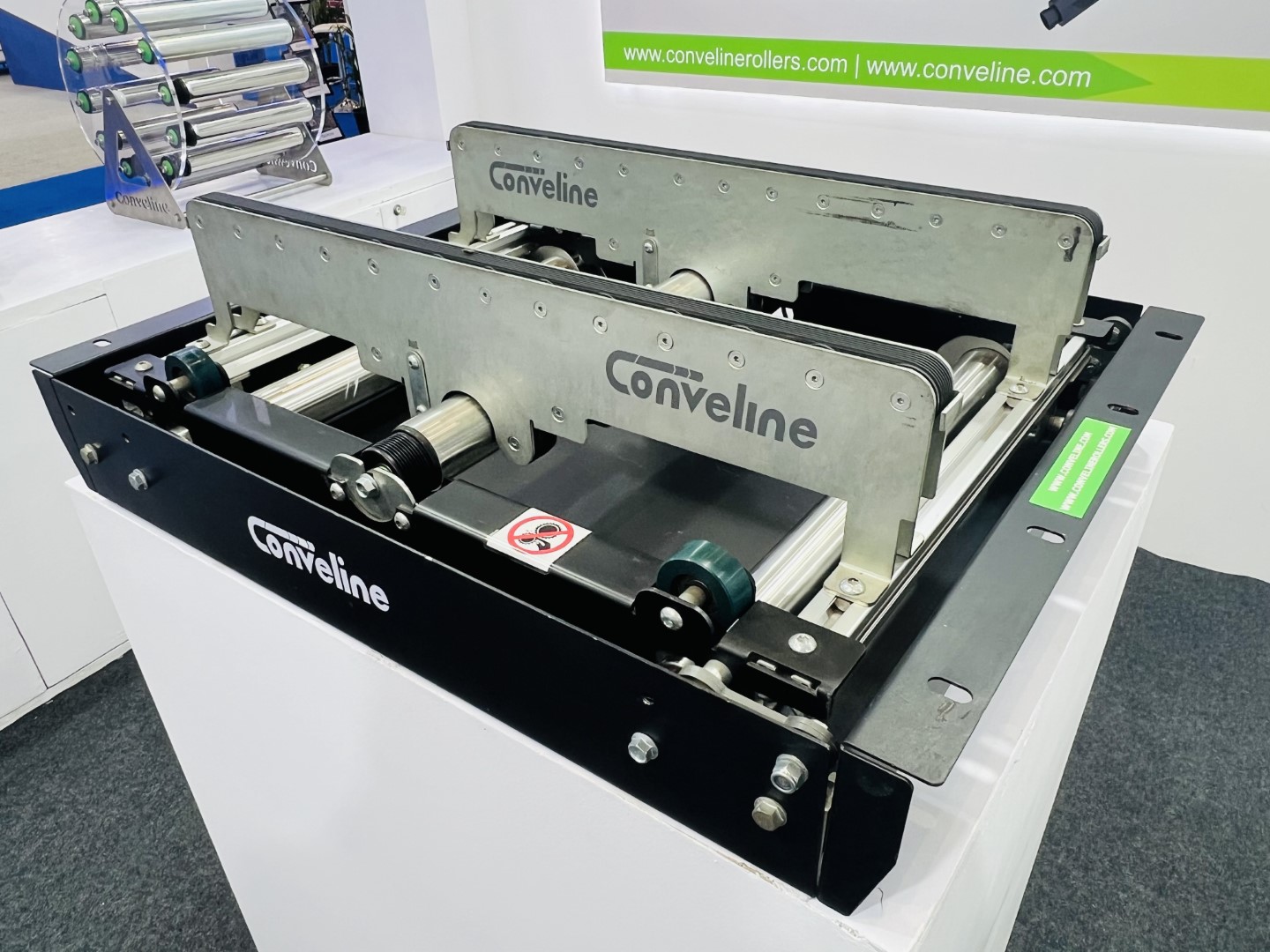

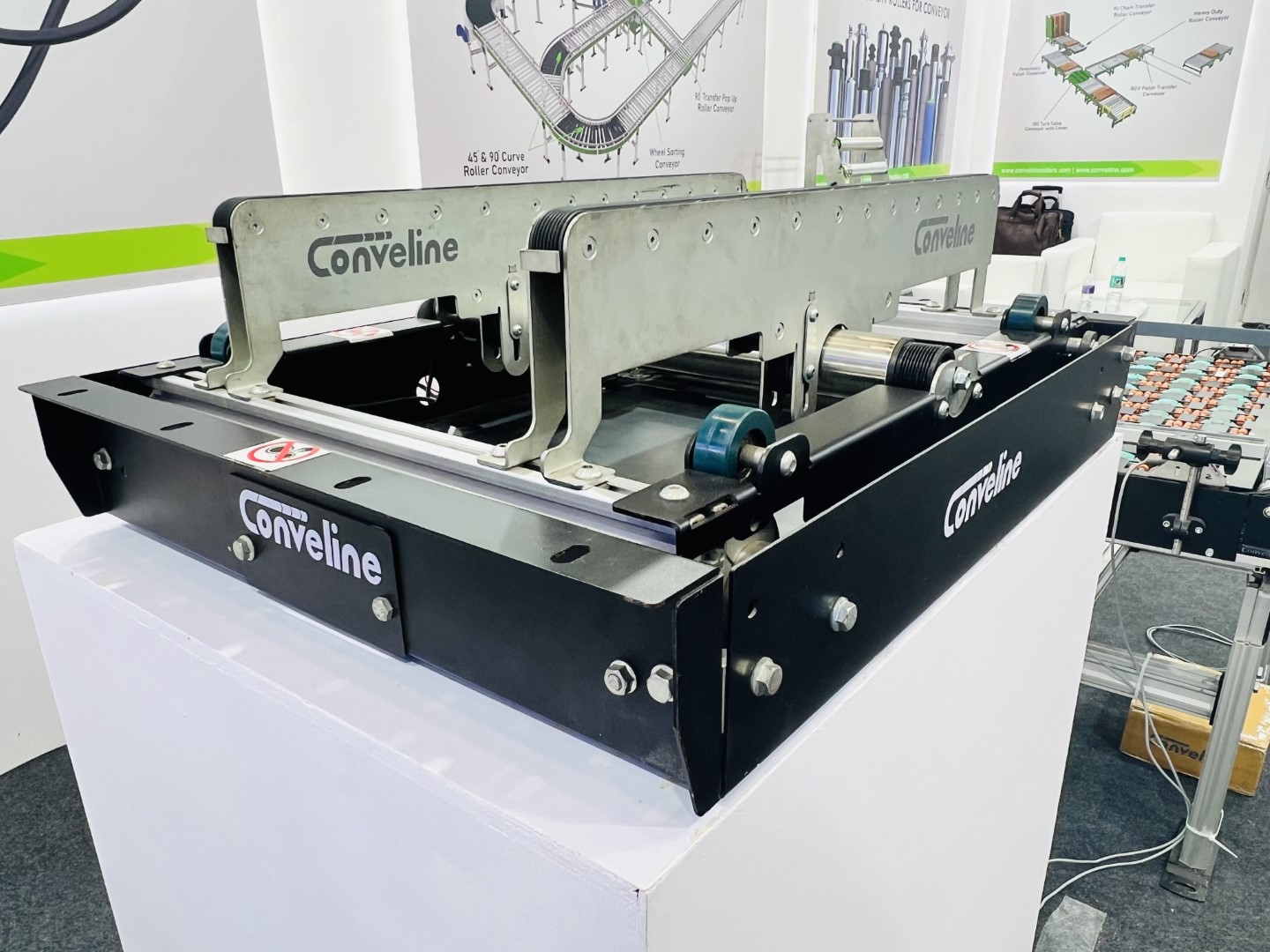

Cross Transfer Unit Manufacturer

Conveline Systems, a trusted Cross Transfer Unit Manufacturer, offers efficient 90-degree transfer conveyors ideal for sorting or transferring products at a right angle. Powered by RM50 Conveline Power Rollers and controlled with the RC50 Control Card, this unit ensures durability, reliability, and easy operation. The advanced MDR technology allows for precise product positioning during transfers, enhancing productivity and reducing errors. Designed for simplicity and convenience, the ergonomic structure makes operation hassle-free for users. Perfect for various manufacturing and distribution needs, Conveline’s 90-degree transfer unit provides a seamless and efficient solution for moving products from one line to another. Whether for sorting or transferring, this conveyor ensures smooth, accurate handling of products at every stage of the process.

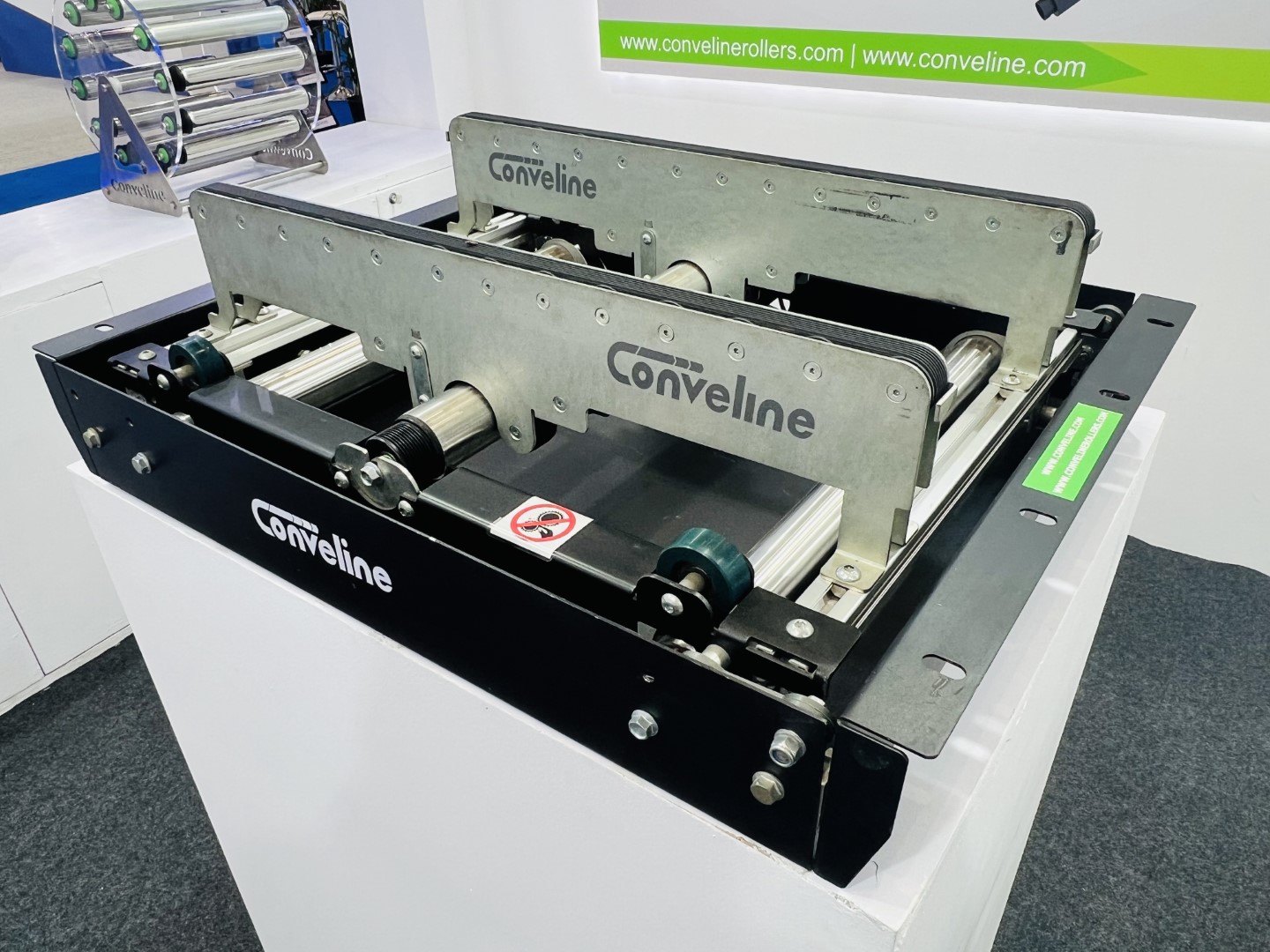

Product Features

- Highest throughput possible:

- Best lead times

- For standard and custom systems plus local planning support by experienced application engineers

- 24V drive options

- For energy efficiency all the way

- Flexible side guides

- Roller conveline make

- For fast and easy maintenance and top mounting

- Versatile Aluminium side profiles

- For simple and flexible installation and system extensions

- High-speed field bus

- As open platform and future-proof control system

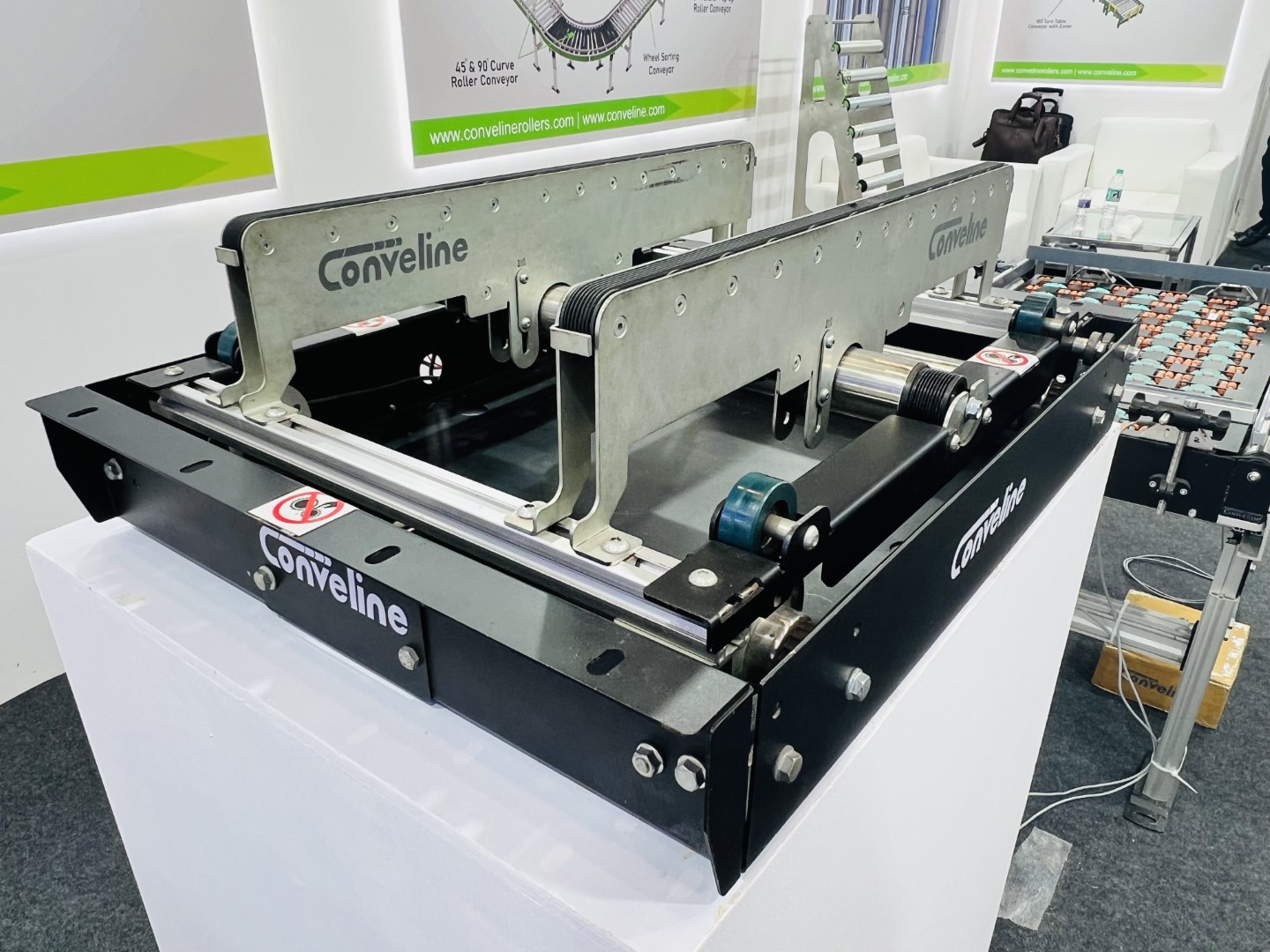

Options

- Motor Mounting positions

- Adjustable support leg

- Fully adjustable Guide and Fixed guide

- Customise conveyor layout

- Automations support

- Diverter, Merger, Stopper, etc application

Application

With over more than 50 variants, you can show your customers how to use their processes accelerate. conveline intralogistics continues to work on the expansion and optimization of the pre-roofed systems, so that you are always up-to-date with the latest technology. All best practice solutions can be adapted to the individual needs and building conditions on site at your customers. If you have any questions, please contact our conveline intralogistics application support.

- Complex three-dimensional track-layouts without separating points and transitions with one conveyor

- Logistic and warehousing application

- Tote and boxes handling

- Post and parcel application

- End of line automation for carton handling

- Product buffer or accumulation application

- Energy saving application

- 400V and 24V option working

Specifications

| Standard Width (mm) | Module Height (mm) | Sorting Capacity (pph) | Max. Load capacity (kg) | Min. to max. product dimension (mm) | Control 24V Power Roller (conveline make) for Lift and Transport |

|---|---|---|---|---|---|

| 600 | 150 | 1200 to 1800 | 50 | 200 to 800 | Speed 1 m/s |

| 800 | 150 | 1200 to 1800 | 50 | 200 to 800 | Speed 1 m/s |

| As per Requirement | 150 | Based on product weight | 50 | - | Speed 1 m/s |