CONVEYOR AUTOMATION DESIGN CONSULTING

We conceptualize, evaluate cost, and help you make the best decision about your conveyor systems and Conveyor automation investment with strategic production operations.

READ MORE

CLIENT SUPPORT IN CONVEYOR SYSTEM DESIGN

We over-prepare your conveyor design staff, quickly address technical issues, and help you maintain a worry-free conveyor system and automation design.

READ MORE

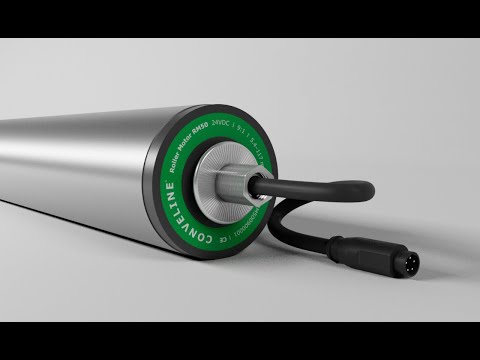

SPEC EXECUTION AND CONVEYOR DESIGN

Our experts validate workability, fill in the gaps, and manage seamless integration. Conveyor Systems operations are execution focused. Execution solutions ensures proper material handling solutions by guiding direction and ensure correct quantities remain in the pick areas which is governed by Conveyor Systems Operations.

READ MORE

WE EXPORT WORLDWIDE

Russia | USA | UAE | Australia | Malaysia | France | Kuwait | Saudi Arabia | Singapore | Switzerland | Qatar | South Korea | Bangladesh | Czech Republic | The Netherlands | Kazakhstan | Nigeria | Vietnam | Oman | Thailand | Mexico | Argentina | Brazil | Canada | India | Japan | Indonesia | New Zealand | Egypt | South Africa | Philippines | Turkey | Greece | Norway | Sweden | Portugal | Spain | Italy | Belgium | Poland | Ireland | Austria | Denmark | Finland | Israel | Iran | Iraq | Lebanon | Jordan | Syria | Libya | Algeria | Morocco | Sudan | Kenya | Uganda | Zimbabwe | Angola | Cambodia | Nepal | Sri Lanka | Myanmar | Afghanistan | Ethiopia | Ghana | Peru | Chile | Bolivia | Honduras | Guatemala | Ecuador | Paraguay | Uruguay | Serbia | Croatia | Bosnia and Herzegovina | Iceland | Luxembourg | Belarus | Ukraine | Lithuania | Latvia | Estonia | Georgia | Armenia | Azerbaijan | Yemen | Bahrain | Cyprus | Maldives | Brunei | Bhutan | Laos | Mauritius | Seychelles | Barbados | Jamaica | Trinidad and Tobago | Fiji | Solomon Islands | Micronesia | Vanuatu | Malta | Albania | Moldova | Slovenia | Macedonia | Montenegro | Kosovo | Suriname | Guyana | Belize | Nicaragua | El Salvador | Panama | Costa Rica | The Bahamas | Eswatini | Botswana | Namibia | Lesotho | Zambia | Malawi | Rwanda | Burundi | Djibouti | Eritrea | Somalia | Chad | Republic of the Congo | Democratic Republic of the Congo | Gabon | Equatorial Guinea | Guinea | Guinea-Bissau | The Gambia | Liberia | Sierra Leone | Togo | Benin | Burkina Faso | Ivory Coast | Senegal | Mali | Niger | Mauritania | Mozambique | Madagascar | Turkmenistan | Uzbekistan | Tajikistan | Kyrgyzstan | Palestine | East Timor | China | Pakistan | Hungary | Romania | Bulgaria | Slovakia | Venezuela | Colombia

READ MORE